Solder joint voiding is tough to deal with. When attaching components, such as power amplifiers/transistors or QFNs, the larger the footprint the bigger the challenge.

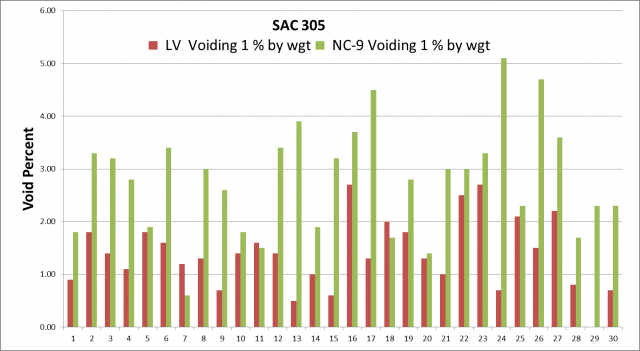

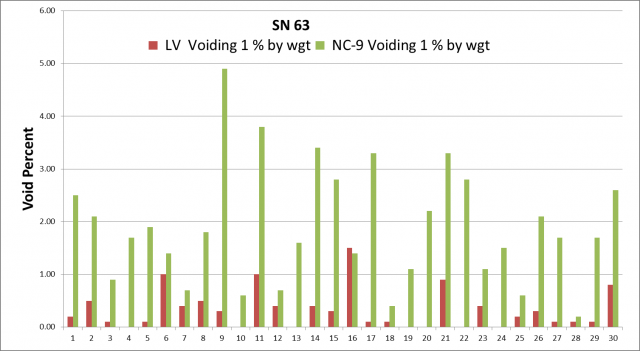

For some time now I have been suggesting the use of a perform with flux coating as an approach to help reduce voiding. Logically, if you introduce less flux you entrap less flux. Our NC-9 flux coating is a proven solution. Many customers are already aware of its advantages, realizing a 50% drop in overall voiding in some cases. However, given the increasing performance demand on assemblies, the need for even lower voiding is emphasized. Simply removing the paste and adding a preform is no longer enough. In an effort to meet this requirement, The Indium Corporation has developed the next generation of flux coatings. Our LV-series flux coating is designed to address void reduction primarily, but has additional advantages as well. LV offers:

- A uniform, repeatable coating as low as .5% by wieght

- Halide-free without sacrificing strength

- Low residue gloss coating does not clog pick & place nozzles

The graphs below show void reduction improvement over our current NC-9 coating for SAC305 and SN63 assemblies.

To receive the complete details of this report, or, if you would like assistance with void reduction in your application, contact me directly.