The following is an example of how a simple procedure like cleaning a soldering iron tip can make a world of difference in the quality of a solder joint. Eric Bastow responded to a customer after doing some testing in the lab – and confirming that a clean iron tip contributes to a clean solder joint:

“As I mentioned in our conversation, I did not think that a flux coated preform would fare any worse than a cored wire in a hand soldering application where charring is concerned. Rosin is rosin is rosin, regardless of whether it is within a cored wire or coating a solder preform. I did a quick experiment to see what would happen.

“As I mentioned in our conversation, I did not think that a flux coated preform would fare any worse than a cored wire in a hand soldering application where charring is concerned. Rosin is rosin is rosin, regardless of whether it is within a cored wire or coating a solder preform. I did a quick experiment to see what would happen.

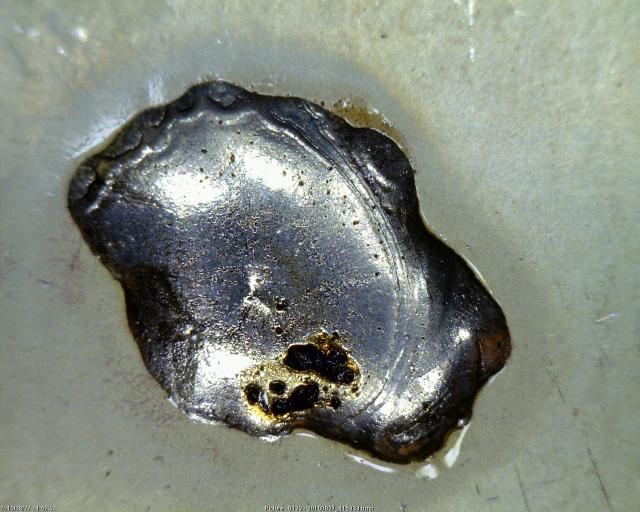

Using a Weller WS80 soldering station, set to an abusively high temperature of 850F/455C, I soldered some .250” square x .005” thick Sn63 preforms (folded-up as small as I could do by hand), flux coated with 1% NC9, to a nickel metallized FR4 test coupon. The contact time of the iron to the solder was ~5 seconds. The results look pretty good. The charred  flux that you do see is flux that burnt to the iron and was transferred to the solder from the previous preform. I would anticipate this sort of appearance with a flux cored wire, as well, used under these conditions. I believe that with frequent cleaning of the tip, the amount of unsightly flux residue with be minimal, especially if a more appropriate iron temperature were used.” -Eric

flux that you do see is flux that burnt to the iron and was transferred to the solder from the previous preform. I would anticipate this sort of appearance with a flux cored wire, as well, used under these conditions. I believe that with frequent cleaning of the tip, the amount of unsightly flux residue with be minimal, especially if a more appropriate iron temperature were used.” -Eric

The bottom image is what happens when you don't clean a soldering iron tip.

Soldering Basics