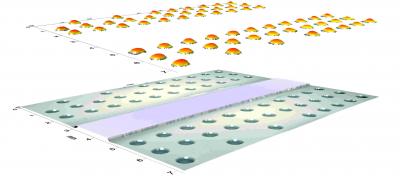

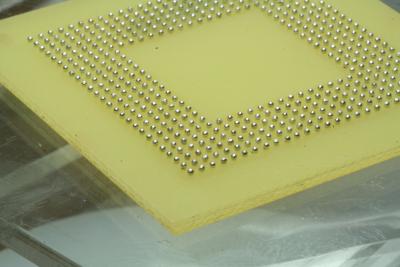

Pin transfer is a way of selectively depositing a semi-solid or liquid material (like a solder paste or ball-attach flux). It is commonly used to apply flux to BGA (ball-grid-array) pads to promote subsequent solder sphere attachment. Pins are dipped into a reservoir of material where the pins are coated with flux, paste, or epoxy. Next, the pins are lifted out of the material reservoir and placed down onto the BGA pads. A portion of material that traveled on the pins sticks to the pads as the pins are lifted away. As archaic as it sounds, this method is quite repeatable – and used extensively in semiconductor packaging. This method of application is used because it deposits flux very quickly, and can compensate for changes in substrate height.

Pin transfer fluxes are specially designed with rheological characteristics to help optimize the amount of material that is picked up and placed on the pads. Other materials can also be pin transferred. Pin blocks are used to transfer solder paste and epoxies in a range of applications. Sometimes only one large pin is needed to transmit flux, this is called flux stamping. Stamp transfer has the benefit of being simple to set up because there are few parameters that need to be adjusted.